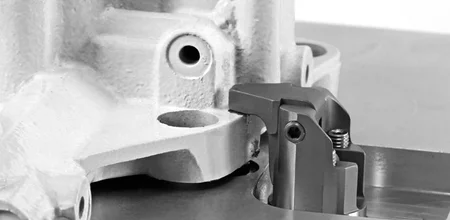

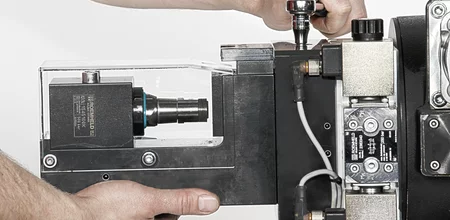

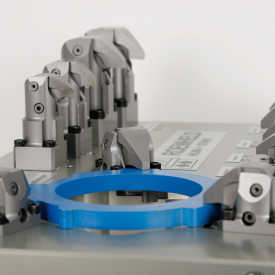

ROEMHELD North America is thrilled to introduce the revolutionary Hilma.UC 125 machine vise, a true concentric clamp designed for versatility and efficiency in machining operations. This innovative solution, presented by STARK Spannsysteme GmbH, a proud member of the ROEMHELD Group, promises to streamline set up for different workpieces while reducing the need for multiple clamping…

WELCOME TO

ROEMHELD

North America

The worldwide market leader in stationary workholding, quick die change, assembly, and handling.

Free process evaluations and concept designs >

CONTACT US

CONTACT USLet’s Collaborate

Do you need help finding the right product or need a specific solution for your application?

We can help.

As specialists in workholding and handling, we offer holistic and process-oriented solutions.

Let’s collaborate to find the best solution for you.

ROEMHELD North America is a joint venture formed in 1982 between ROEMHELD GmbH, a global leader in highly engineered power workholding systems, and Carr Lane Manufacturing, America’s premier tooling component supplier.

We provide highly engineered solutions for Power Workholding, Zero Point Mounting & CNC Vises for Precision Metal Cutting, Assembly & Handling Technology, and Hydraulic & Magnetic Die Clamping Systems for Quick Mold and Die Changes.